Text by William Miller

There is a science to flavour. The field of food science has evolved significantly to meet the growing demands for food composition and characteristic determination. Trends and demands of consumers, the food industry, and national and international regulations challenge food scientists as they work to monitor food composition, authentication and to ensure the quality and safety of the food supply1.

For example, regulatory compliance with the US Food & Drug Administration’s (FDA) Nutrition Labeling and Education Act and other country-specific regulatory requirements, mandate disclosure and labelling of food ingredients and their respective quantities. Also, more consumers are interested in food product nutrient content, so that they may make informed purchase decisions based on diet and health.

Lastly, product quality management and competitive pricing are driving industry trends in analytical methods and technologies. Analytical methods must be applied across the entire food supply chain to achieve the desired final product quality1. Cost reduction initiatives and workforce downsizing mandate the implementation of economical, easy-to-use technologies. Thus, simple, cost-effective, standardized technology platforms, providing rapid, accurate results, are of the essence for today’s food and beverage space.

Achieving these industry requirements can be a challenge. However, YSI Life Sciences’ family of Biochemistry Analyzers can meet these demands though automated, plug-and-play analytical solutions for raw materials testing, food R&D, in-process monitoring and final product testing – especially when rapid, precise and economical analysis of saccharides, amino/organic acids, alcohols and electrolytes are required.

YSI Biosensor Technology Advantage

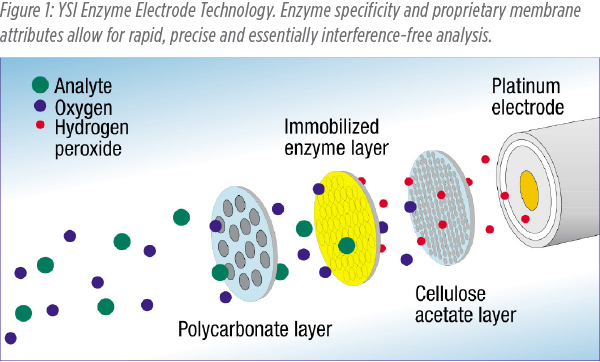

YSI’s innovative enzyme electrode technology harnesses the power of enzymatic specificity and catalysis to provide a rapid, precise analytical tool. Enzymes, which are powerful biological catalysts, can accelerate reactions by factors of at least one million2. Additionally, enzymes are highly specific for both the reaction catalyzed as well as its choice of substrate2. YSI immobilizes substrate-specific enzymes between two selective interfering membranes and couples the membrane component to a platinum electrode, which results in a highly specific measurement for a given substrate.

To better explain how the enzyme electrode technology works, an example of a common food ingredient analysis, i.e., dextrose (D-glucose), will be used. An enzyme probe is fitted with a three-layer membrane containing immobilized glucose oxidase enzyme in the middle layer. The face of the probe, covered by the membrane, is situated in a buffer-filled sample module into which the dextrose sample is injected by the instrument. The dextrose diffuses through the first membrane. When it contacts the immobilized glucose oxidase, it is rapidly oxidized, producing hydrogen peroxide (H2O2).

H2O2, in turn, passes through the inner membrane and is oxidized at the platinum anode, producing electrons. A dynamic equilibrium is achieved when the rate of H2O2 production and the rate at which H2O2 leaves the immobilized enzyme layer are constant and is indicated by a steady state response. The electron flow is linearly proportional to the steady state H2O2 concentration and, therefore, to the concentration of the substrate. All of this occurs in a matter of seconds, which results in a sample analysis cycle of 60 seconds or less per chemistry analyzed. The figure below illustrates this process more clearly.

Sample analysis requires little or no preparation due to the YSI Biochemistry Analyzer’s unique sample chamber design and membrane characteristics, which makes the enzyme electrode impervious to sample color, pH, turbidity, cell concentrations, salts, proteins detergents and other low molecular weight interferences. Additionally, only small sample volumes are needed, ranging between 10 – 50 µl.

The YSI 2900 Series Biochemistry Analyzers are highly flexible, modular platforms with a range of configurations, options and accessories to meet the various needs of the food process cycle, regardless of scale of operations (Figure 2).

Up to six different chemistries can be measured simultaneously using automated, high-throughput options, i.e., 96-well plates, stat mode for immediate process sample checks and automated on-line sample analysis for food and beverage process and effluent streams. Each analyzer offers an intuitive graphic user interface, onboard training videos and multiple data management options. As compared to other conventional methods, such as HPLC, YSI Biochemistry Analyzers offer a low-cost alternative for both initial capital investment and cost per chemistry test ($0.10 – $0.70 USD/sample). Other features include low maintenance requirements and easy product changeover.

Industry Applications

For over two decades YSI’s Biochemistry Analyzers have been the analytical technology of choice for many major food and beverage manufacturers. The operations in which the YSI biosensor technology has been utilized spans from raw materials analysis through final product QC testing and effluent monitoring. The table at right lists some of the food and beverage applications in which YSI Biochemistry Analyzers have been employed.

For over two decades YSI’s Biochemistry Analyzers have been the analytical technology of choice for many major food and beverage manufacturers. The operations in which the YSI biosensor technology has been utilized spans from raw materials analysis through final product QC testing and effluent monitoring. The table at right lists some of the food and beverage applications in which YSI Biochemistry Analyzers have been employed.

Conventional methods can be costly and/or time consuming. The YSI biosensor technology offers a low cost alternative while providing rapid sample analysis due to the characteristics of the immobilized enzyme membrane technology. Additional time savings can be realized as no sample preparation is required in most cases. For example, analyzing glucose and sucrose in high salt food samples is easily achieved with no sample preparation. In contrast, trying to perform this type of analysis using HPLC is difficult, and sometimes impossible, due to high salt interference. Other food and beverage applications in which the YSI enzyme electrode technology has replaced other analytical methods include various analyte monitoring of ice cream products, beer production, sugar-free food and beverages, dry bakery mixes and animal food.

As most of this discussion has implied at-line or off-line laboratory use, YSI Biochemistry Analyzers have been successfully employed for on-line process monitoring. With industry trends moving towards automated, online and inline monitoring of food and beverage processes, real-time monitoring of food ingredients and effluent can be achieved with YSI’s online monitoring and control system. This bolt-on function automatically draws a fluid sample from the process stream and delivers the sample directly to the YSI Biochemistry Analyzer. The sampling is performed aseptically, and the online analytical results can be communicated immediately to your SCADA or process management system for real-time data acquisition and/or feedback control.

In conclusion, food industry trends, regulatory requirements and needed analytical improvements dictate the requirement for simplified, low-cost, rapid and precise analysis of food and beverage ingredients throughout the entire process train. These attributes should be coupled with versatile, scale-independent technologies to provide standardized, plug-and-play analytical platforms which spans across the food and beverage cycle.

YSI’s unique enzyme biosensor technology helps satisfy this need for common food ingredients including mono- and di-saccharides, alcohols, amino acids and more. If you would like to learn more about YSI’s food and beverage analytical solutions, please contact us at www.ysi.com/lifesciences, info@ysi.com or 800-765-4974.

References

[1] S. Suzanne Nielsen, ed. Food Analysis. New York: Springer, 2010.

[2] Stryer, Lubert. Biochemistry. New York: W.H Freeman and Company, 2000.

Canadian Food Business

Canadian Food Business