Bottom: BUCHI Automated Kjeldahl solutions featuring the KjelMaster K-375, the most automated Kjeldahl system on the market today.

By William Ickes

Due to its critical role in diet and health, measuring the protein content of food is more important than ever. Food production companies need to monitor protein content at multiple points along the food process chain. The three most common techniques used to measure protein content are Kjeldahl, Dumas (combustion), and NIR (near-infrared spectroscopy). While all three are valid, each of these methods comes with unique advantages or challenges. BUCHI Corporation is unique in that we have expertise in all three of these techniques. This expertise can applied to help you decide which technique will best work for you.

The three major areas in the food production process chain include: raw material inspection, process control, and final analysis for label claim. As processed food, beverage, feed, and forage pass through the production lifecycle, different techniques may be considered to measure protein content. Whether you need fast qualification of raw material, or precise protein declaration of processed goods, the BUCHI protein solutions portfolio cover it all.

In the warehouse, where raw materials used in food production are initially screened and inspected, it is important to have a rapid and comprehensive analysis that can quickly give you an indication of the quality of the incoming raw material. Here you will commonly find techniques like NIR due to its rapid measurement, typically less than 20 seconds, and its ability to perform multicomponent analysis such as measuring protein, fat, moisture, ash, and many other components simultaneously.

In the production line, it is important to measure protein content and other components to ensure that the formulations meet specifications. Here, a rapid and comprehensive technique such as NIR should be considered. In addition to at-line sampling possibilities, an on-line NIR sensor can be integrated to a feeder, mixer, conveyor belt, or product pipe to provide rapid and continuous measurement results in-process. Measurements may be incorporated into a control system for real-time process adjustments. On-line control helps to ensure goods with consistent quality while maximizing production efficiency and profitability. BUCHI also has expertise in this technique with our NIR-Online solution.

In the R&D laboratory, you need a primary technique such as Kjeldahl for measuring protein so that you can accurately and reliably calibrate your NIR instrumentation. It is also used to help determine the protein content of unique formulations in which NIR calibrations have not been developed.

In the QC laboratory, it is important that your method for determining protein content is compliant with official regulations such AOAC, DIN, an ISO. In this environment Kjeldahl and Dumas combustion are commonly employed.

Now that we’ve taken a look at the different places in the process chain that require protein analysis, let’s take a brief look at the different techniques and the factors that will determine which technique is best suited.

Kjeldahl is a well-established primary method for determining the protein content in all kinds of food products. It consists of digesting the sample in sulfuric acid and catalyst at a temperature of 420 C for approximately 90 minutes until all organic material is digested in the sample. The nitrogen contained in the amino acids of the protein are released from the sample matrix and converted to ammonium sulfate. Following digestion, the sample digestion mixture is diluted with deionized water before being placed on a steam distillation system. Strong base in the form of sodium hydroxide is added to the sample mixture in excess to completely alkalize the sample and liberate ammonia gas. The ammonia gas is steam distilled into a receiving solution consisting of boric acid solution. When the ammonia reacts with the boric acid solution it forms an ammonium borate complex which raises the pH of the receiving solution. The receiving solution is then titrated to the original pH of the boric acid solution with standardized sulfuric or hydrochloric acid. If the sample weight and milliliters titrated for the sample is known, you can calculate the nitrogen content which is then converted to protein content with a correction factor.

Kjeldahl is a well-established primary method for determining the protein content in all kinds of food products. It consists of digesting the sample in sulfuric acid and catalyst at a temperature of 420 C for approximately 90 minutes until all organic material is digested in the sample. The nitrogen contained in the amino acids of the protein are released from the sample matrix and converted to ammonium sulfate. Following digestion, the sample digestion mixture is diluted with deionized water before being placed on a steam distillation system. Strong base in the form of sodium hydroxide is added to the sample mixture in excess to completely alkalize the sample and liberate ammonia gas. The ammonia gas is steam distilled into a receiving solution consisting of boric acid solution. When the ammonia reacts with the boric acid solution it forms an ammonium borate complex which raises the pH of the receiving solution. The receiving solution is then titrated to the original pH of the boric acid solution with standardized sulfuric or hydrochloric acid. If the sample weight and milliliters titrated for the sample is known, you can calculate the nitrogen content which is then converted to protein content with a correction factor.

Dumas combustion is a method for determining protein content in various food products. It consists of combusting the sample at a high temperature of 910 C in the presence of oxygen to convert all the organic components of the sample into gases. Many gases are generated in this process; all except the nitrogen and carrier gas, which in this case is CO2, are removed at different stages within the instrumentation. In the final stages, nitrogen and carrier gas is analyzed by a thermal conductivity detector. The system then converts the conductivity response to nitrogen content based on a calibration with reference materials of known nitrogen content.

NIR is a method for determining protein content and various other parameters in many products. It is a spectroscopic method in which the sample is illuminated by light from the near-infrared region of the electromagnetic spectrum. The light is absorbed, scattered or reflected by the sample based on its composition (e.g. protein, moisture, fat). The resulting signal, or spectra, may then be correlated to the sample’s identity, or quantitative parameters, such as protein content, that have been determined from a primary analysis such as Kjeldahl. Once a calibration curve is generated, the composition of routine “unknown” samples may be measured.

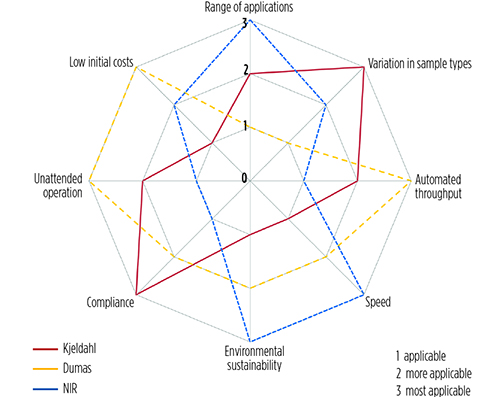

Now that we understand each technique, we can see which technique is better suited for the different tasks. The spider graph below represents different considerations for each technique and correlates which technique is best suited to accomplish project goals while considering limited resources.

In conclusion, Kjeldahl is a technique that can handle all kinds of sample matrices and has the most official methods out of the three techniques. It can be very automated and has a portfolio range that can fit most budgets. It is most commonly found in the R&D and QC label claim laboratories.

Dumas is a technique which can handle homogenous, protein-rich samples in both the solid and liquid form. It has a significant number of official methods and is commonly used in the QC setting. The strength of the Dumas combustion technique is that it has a fast four-minute analysis time and does not require hazardous chemicals. If you need to quickly re-analyze a questionable sample, Dumas can do this quickly.

NIR is a technique that can handle all kinds of samples. It is the fastest technique with an analysis time of less than one minute and has the added value of being able to perform multicomponent analysis. It does require upfront calibration development unless a global calibration solution already exists, but the potential return on investment is enormous once the calibrations are implemented. Moreover, it is the only technique of the three that can detect adulterants.

No matter what your needs are for measuring protein content, BUCHI has a solution for you. If you would like to find out more about our Kjeldahl, Dumas, or NIR solutions for food analysis, please contact us at www.buchi.com/us or call (302) 652-3000.

William Ickes is the Kjeldahl and Dumas Product Manager for BUCHI Corporation

Canadian Food Business

Canadian Food Business